Sustainability & Impact

Expert Recycling Solutions

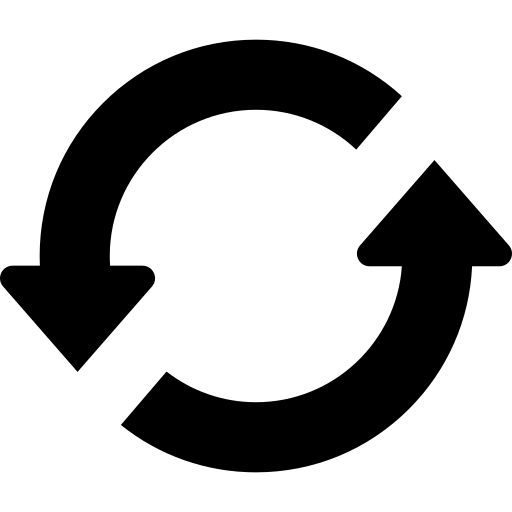

ReEarth is engineered for sustainability at scale. Our LCA-validated, zero-waste operations recover critical battery metals through AI-optimized hydrometallurgy—spanning sample analysis, pilot validation, and commercial production. By eliminating landfill disposal, recycling process water in closed loops, and automating every critical step, we redefine battery recycling as a regenerative industrial system.

From black mass processing to battery-grade metal recovery, every molecule is tracked, every process optimized, and every output aligned with long-term environmental and economic value.

Our Sustainability Framework

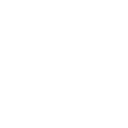

By embedding sustainability into design and scaling it through scientific innovation, we enable circular systems that reduce waste, recover value, and power a resilient clean-energy future.

End-to-end recycling ensures lithium, cobalt, and nickel are continuously regenerated into premium battery-grade feedstock—eliminating resource loss and supply volatility.

Smart reactors, predictive maintenance, and real-time controls maximize yields while minimizing energy, water, and chemical consumption.

Closed-loop water systems recycle and reuse process water, significantly reducing freshwater dependency and industrial discharge.

Our Process

EPR-aligned sourcing with complete chain-of-custody visibility.

Robotic, dust-free crushing eliminates human exposure and material loss.

Hydrometallurgy optimized in real time for maximum yield and purity.

Lifecycle assessment ensures continuous carbon, water, and impact optimization.

Impact Areas

ReEarth reduces lifecycle emissions by up to 70% versus conventional mining, accelerating decarbonization across the EV value chain.

By regenerating lithium and critical metals domestically, ReEarth strengthens India’s lithium independence and supply-chain resilience.

Zero landfill disposal transforms hazardous battery waste into long-term economic and environmental value.

Impact Area

ReEarth reduces lifecycle emissions by up to 70% versus conventional mining, accelerating decarbonization across the EV value chain.

By regenerating lithium and critical metals domestically, ReEarth strengthens India’s lithium independence and supply-chain resilience.

Zero landfill disposal transforms hazardous battery waste into long-term economic and environmental value.

All materials are recovered, reused, or regenerated through closed-loop processing—no landfill disposal.

Through continuous Lifecycle Assessment (LCA) monitoring across all operational stages.

We provide transparent, traceable data aligned with EPR, ESG, and regulatory frameworks.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast